AQUA ROVAL Cold Galvanizing Compound

Environmentally friendly water-based type.

Equivalent anti-corrosion performance to hot-dip galvanizing.

AQUA ROVAL Cold Galvanizing Compound contains 95% pure zinc powder in its dry film.

It is an environmentally friendly water-based type while keeping the outstanding anti-corrosion ability of ROVAL.

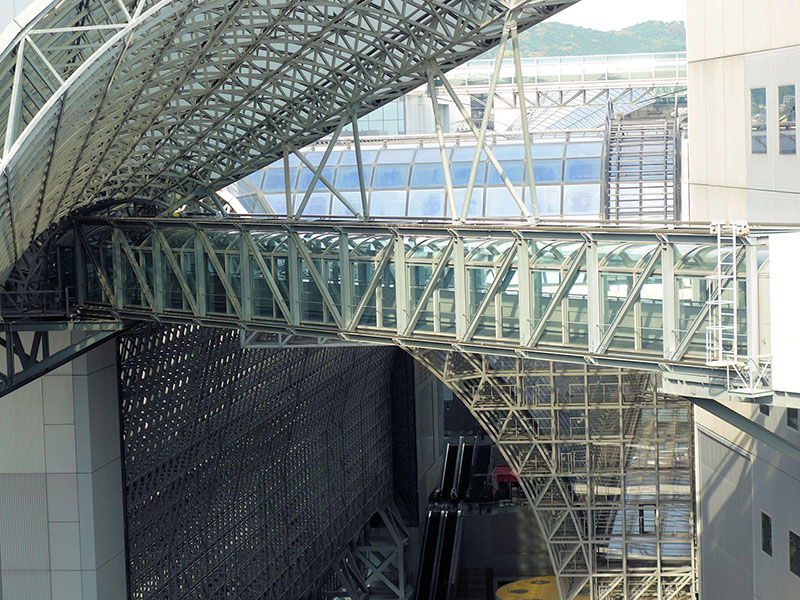

Compared to ROVAL, AQUA ROVAL cuts VOC by 93%, has no thinner odor, and no fire hazards. You can use it with confidence in shopping centers, train stations and public facilities.

Since AQUA ROVAL is simply applied in standard temperatures, it is called “Cold galvanizing compound”.

Meets ASTM A780, ISO1461

>> View Gallery

Applications

Application methods

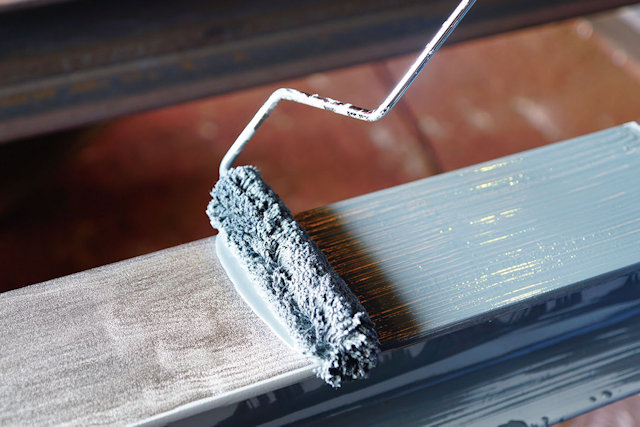

Brush / Roller

Dilution by water — 0 ~ 2%

<Recommended>

Brush: Use chemical fiber brush. Hair is long and soft, hold more paint.

Roller: Hair length is about 12 or 13 mm, hold more paint.

Conventional / Air-less spray

Conventional spray

Gravity feed spray gun

Nozzle size — 2.0 ~ 3.0 mm

Pressure — 0.3 MPa

Dilution by water — 0 ~ 5%

Air-less spray

Tip size — above 0.017 inches (e.g. 517)

Pressure — above 20 MPa

Gun filter — #50 ~ 60

Dilution by water — 0 ~ 2%

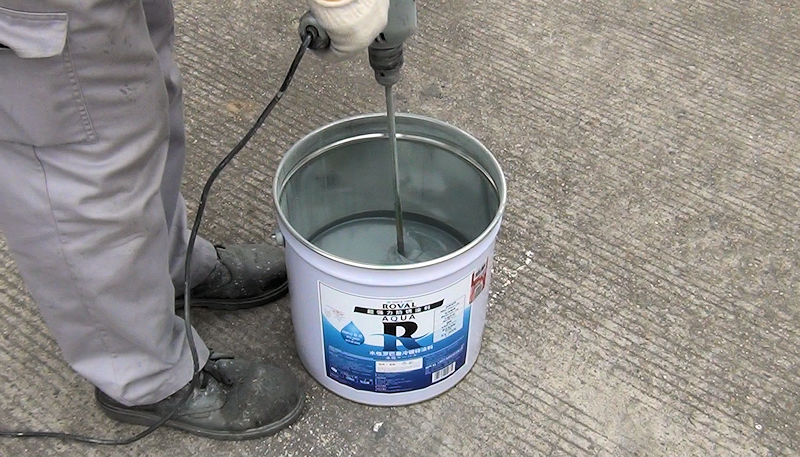

1. Making paint

AQUA ROVAL pots are sold with their zinc powder and paint solution packaged separately.

Just before use, stir the paint solution, then add the zinc powder little by little.

(Powder : Liquid = 4 : 1)

After that, stir the mixture well with a power paint mixer until the lumps disappear.

Pot-life: within 8 hours after mixing

2. Proper surface preparation

Degrease thoroughly. (Applying water-based paint on oil will repel it)

Basic matter

When applying on galvanized surfaces, use a hand tool to remove white rust.

For steel surfaces, remove all contamination, oil, mill scale, rust and old paint by sandblasting or using a power tool to expose the clean steel surface.

If old paint film remained

Using power tool, remove rust and loosely adhering paint.

*Since AQUA ROVAL contains no solvent, it does not attack the old paint film. Therefore, it can applied on the tightly adhering old paint film. However the anti-rust effect cannot be achieved unless it is applied directly to the metal surface.

3. Sufficient film thickness

Apply two coats. (Each coat: 40μm)

Total dry film thickness = more than 80μm

Do not spread the paint too thin.

Anti-corrosion performance is proportional to dry film thickness.

Coating interval : above 30min (Depends on temperature and humidity)

Film thickness inspection

Inspect the film thickness using an electromagnetic thickness tester.

Wrong application

Applying product to rusted surfaces

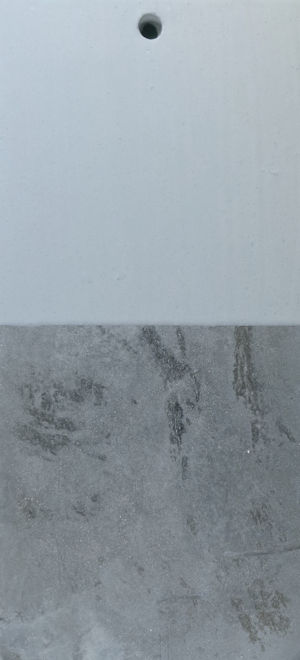

Color weathering of AQUA ROVAL

The film of AQUA ROVAL weathers the same as galvanized materials by exposure. This characteristics makes repaired unapparent.

The color change is proof that the film protects iron by oxidizing zinc in the coating.

This color change is not abnormal and does not affect the rust prevention performance.

The photo below shows a plate with AQUA ROVAL coating on the upper half of a galvanized plate.

|  |

| Before exposure | After 3 months |

Line up & specification

| Recommended film thickness | 80μm (40μm x 2 coats) |

| Theoretical coverage | 500g/m2 (250g x 2 coats) |

| Dry to touch time | 30 minutes (23˚C) |

| Heat resistance | 170˚C |

Meets ASTM A780, ISO1461

| AQUA ROVAL Cold Galvanizing Compound 1kg set (Powder 800g : Liquid 200g) Painting area: 2m2 (2 coats) Packaging: 4 sets / case |

| AQUA ROVAL Cold Galvanizing Compound 5kg set (Powder 4kg : Liquid 1kg) Painting area: 10m2 (2 coats) Packaging: 1 set |

| AQUA ROVAL Cold Galvanizing Compound 20kg set (Powder 16kg : Liquid 4kg) Painting area: 40m2 (2 coats) Packaging: 1 set |