Target products

>> Go to How to use AQUA ROVAL ![]()

Features of ROVAL series

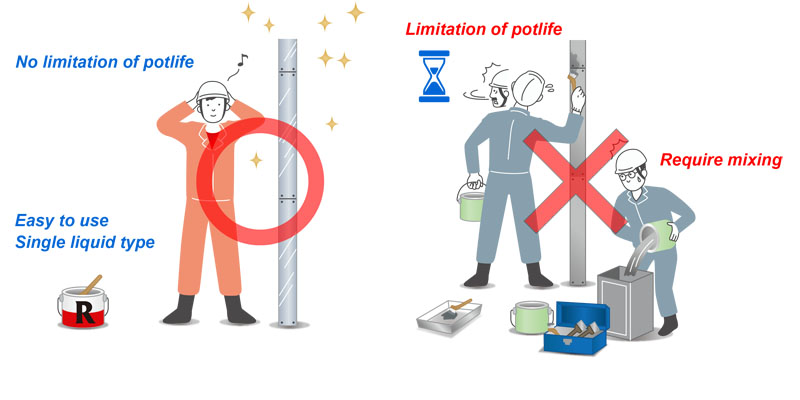

Ready-to-use single liquid type

> Dilution is unnecessary so painting is very easy.

> No troublesome work, like mixing two liquids.

> No limitation of pot-life.

> The rest of the paint can be kept in a closed container.

> Aerosol product lineup.

Video

Application methods

Aerosol spray

Shake the aerosol can 30 times or more.

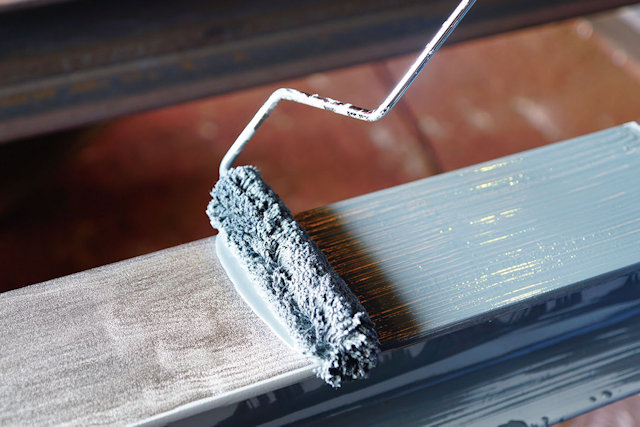

Brush / Roller

Dilution is not required.

Only when the product thickens, use thinner within 5% of paint weight.

<Recommended>

Brush: Hair is long and soft, hold more paint.

Roller: Hair length is about 12 or 13 mm, hold more paint.

Conventional / Air-less spray

Conventional spray

Gravity feed spray gun

Nozzle size — 1.5~2.0mm

Pressure — 0.3MPa

Paint strainer — #100

Dilution — 0~5%(ROVAL, EPO ROVAL), 5~10%(ROVAL SILVER)

Air-less spray

Tip size — above 0.017 inches (e.g. 517)

Pressure — above 20MPa

Gun filter — #50~60

Dilution — 0~5%

Most important factor

ROVAL has to be applied DIRECTLY to metal surfaces.

The direct contact between the zinc and the metal surface will result cathodic reaction.

Never use primers.

Primer will compromise the performance of ROVAL products.

3 important points

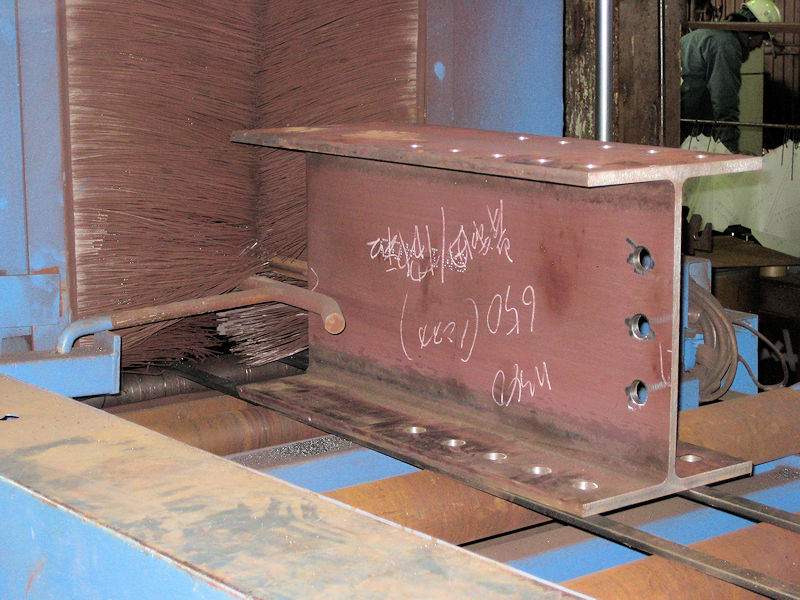

1. Proper surface preparation

When applying ROVAL on galvanized surfaces, use a hand tool to remove white rust.

For steel surfaces, remove all the rust and mill scale by sandblasting or using a power tool to expose the clean steel surface.

>> When is the restoration of old galvanized surfaces required?

2. Adequate agitation

Agitate the products well to obtain uniform density.

Dilution is not required.

*Only when the product thickens, use thinner within 5% of paint weight.

*EPO ROVAL must use a dedicated EPO ROVAL THINNER.

| Product | Type of thinner |

| ROVAL ROVAL SILVER | ROVAL THINNER (or aromatic thinner like Xylene) |

| EPO ROVAL | EPO ROVAL THINNER Never use ROVAL THINNER (Paint agglutination occurs) |

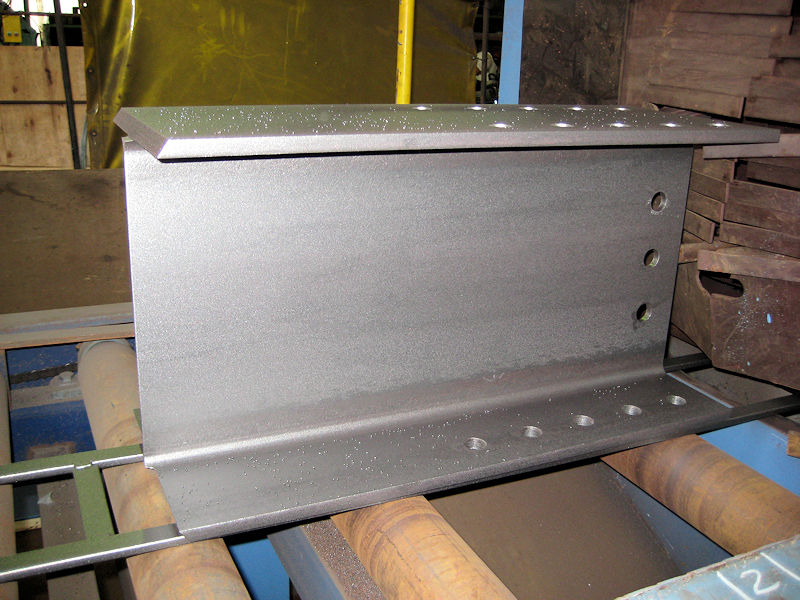

3. Sufficient film thickness

Apply two coats. (Each coat: 40μm)

Total dry film thickness = more than 80μm

Do not spread the paint too thin.

Anti-corrosion performance is proportional to dry film thickness.

Coating interval : 30~60 min

Make sure the paint is dry to touch before applying a second coat.

Film thickness inspection

Inspect the film thickness using an electromagnetic thickness tester.

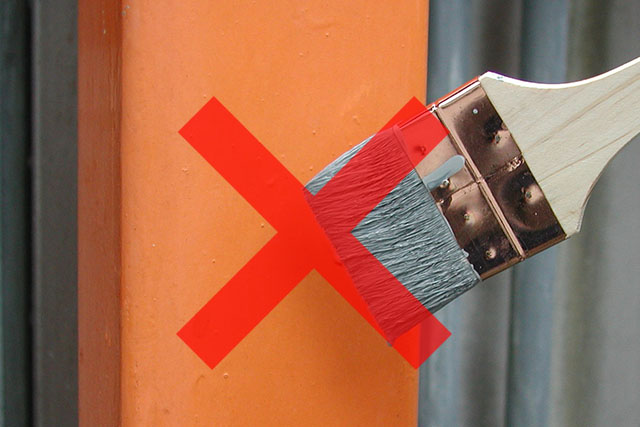

Wrong application

Applying product to rusted surfaces

Applying product to painted surfaces

The importance of surface preparetion

Surface pretreatment directly affect the anti-corrosion performance and service life of coating film.

To get the best anti-corrosion performance, surface pretreatment is very important.

Brushing only after the clean and bare metal surface is exposed out by using sandblasting or power tools to remove the contamination on the metal and galvanizing surfaces.

Results of salt spray experiments under surface preparation conditions