< Contents >

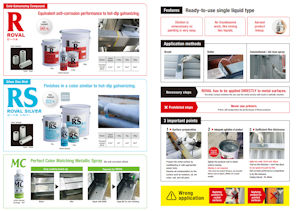

Catalogs

Certificates

Technical documents & TDS

SDS (Safety Data Sheet)

Leaflet

|  |

| <English > | < Japanese > | < Chinese > |

| English A3 English A4 | 日本語 A3 日本語 A4 | 简体中文 A3 简体中文 A4 |

| < Thai > | < Myanmar > | < Vietnamese > |

| ภาษาไทย A3 ภาษาไทย A4 | မြန်မာ A3 မြန်မာ A4 | Tiếng Việt A3 Tiếng Việt A4 |

| < Malay > | < Indonesian > | < Spanish > |

| Bahasa Melayu A3 Bahasa Melayu A4 | Bahasa Indonesia A3 Bahasa Indonesia A4 | Español A3 Español A4 |

Other calatogs

General catalog A3 size |  General catalog A4 size |  Spanish catalog A4 size |

| English 日本語 Japanese 한국어 Korean | English 简体中文 Simplified Chinese 繁体中文 Traditional Chinese ภาษาไทย Thai | Español Spanish |

ROVAL ZC Galvanizing Repair Metallic Spray A4 size |   ROVAL MC Color Matching Metallic Spray for Galvanized materials A4 size | |

| English 日本語 Japanese Tiếng Việt Vietnamese ภาษาไทย Thai Bahasa Melayu Malay Español Spanish | English 日本語 Japanese Tiếng Việt Vietnamese ภาษาไทย Thai Bahasa Melayu Malay Bahasa Indonesia Indonesian Español Spanish |

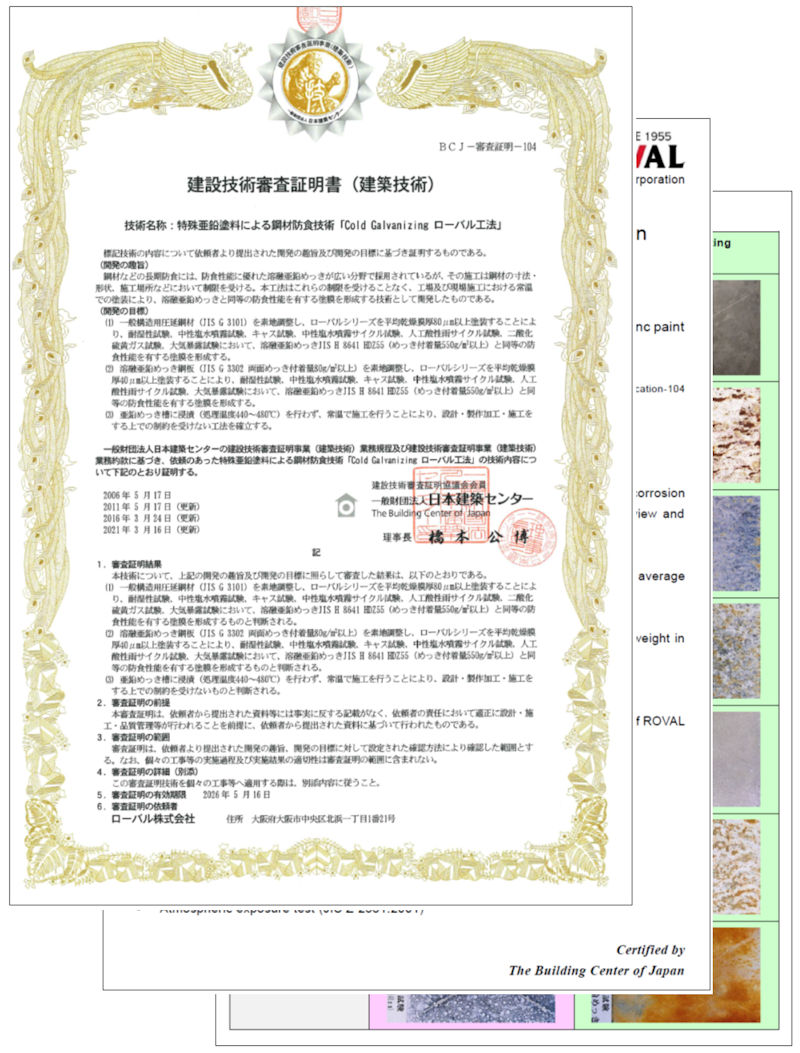

Certified anti-corrosion performance

Cold Galvanizing ROVAL Method

ROVAL has been certified to have equivalent anti-corrosion performance as hot-dip galvanizing by the Council for Construction Technology Review and Certification in Japan.

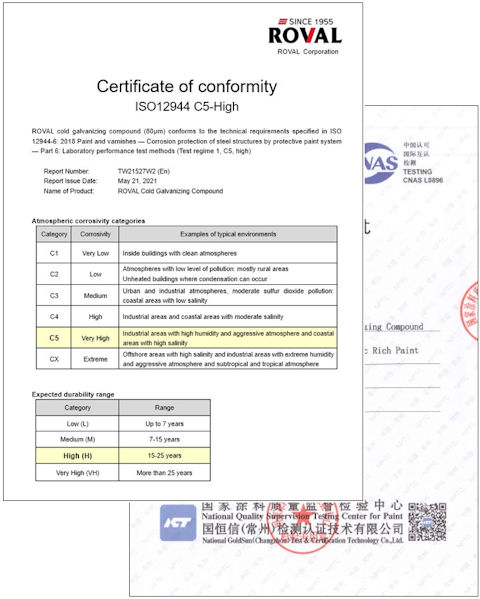

ISO12944 C5-High

ISO12944 : 2018 Paints and varnishes — Corrosion protection of steel structures by protective paint systems

It is an international standard for the protection of steel against corrosion by protective paints systems. The 80 μm coating of ROVAL or EPO ROVAL complies with the technical requirements specified by ISO12944 C5-High.

This means that ROVAL or EPO ROVAL can be expected to have a durability life of 15 to 25 years in C5 corrosive environment.

C5 corrosive environment exposure test result

C5 corrosive environment exposure test result

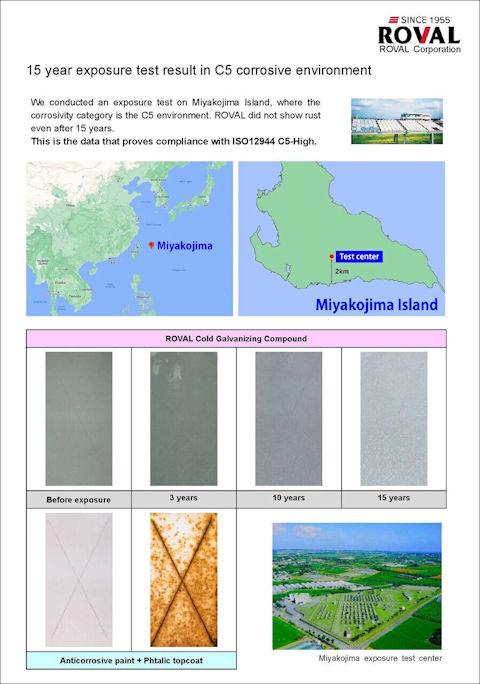

15 year exposure test result in C5 corrosive environment

We conducted an exposure test on Miyakojima Island, where the corrosivity category is the C5 environment. Rust occurred on the entire surface of general paint in 3 years, but ROVAL did not show rust even after 15 years. This is the data that proves compliance with ISO12944 C5-High.

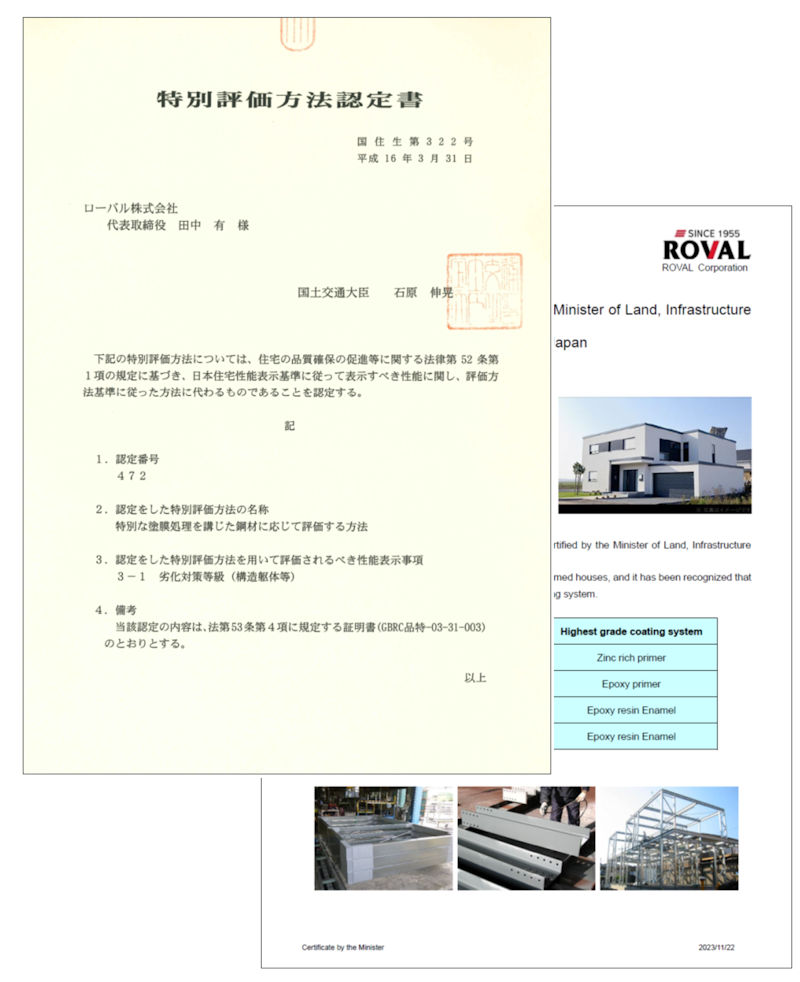

Certified by the Minister of Land, Infrastructure and Transport in Japan

ROVAL’s excellent performance was recognized and certified by the Minister of Land, Infrastructure and Transport in Japan.

This is a law on the anticorrosion performance of steel framed houses, and it has been recognized that ROVAL’s coating is equivalent to the highest grade coating system.

| ROVAL coating system | Highest grade coating system | |

| 1st | ROVAL | Zinc rich primer |

| 2nd | ROVAL | Epoxy primer |

| 3rd | — | Epoxy resin Enamel |

| 4th | — | Epoxy resin Enamel |

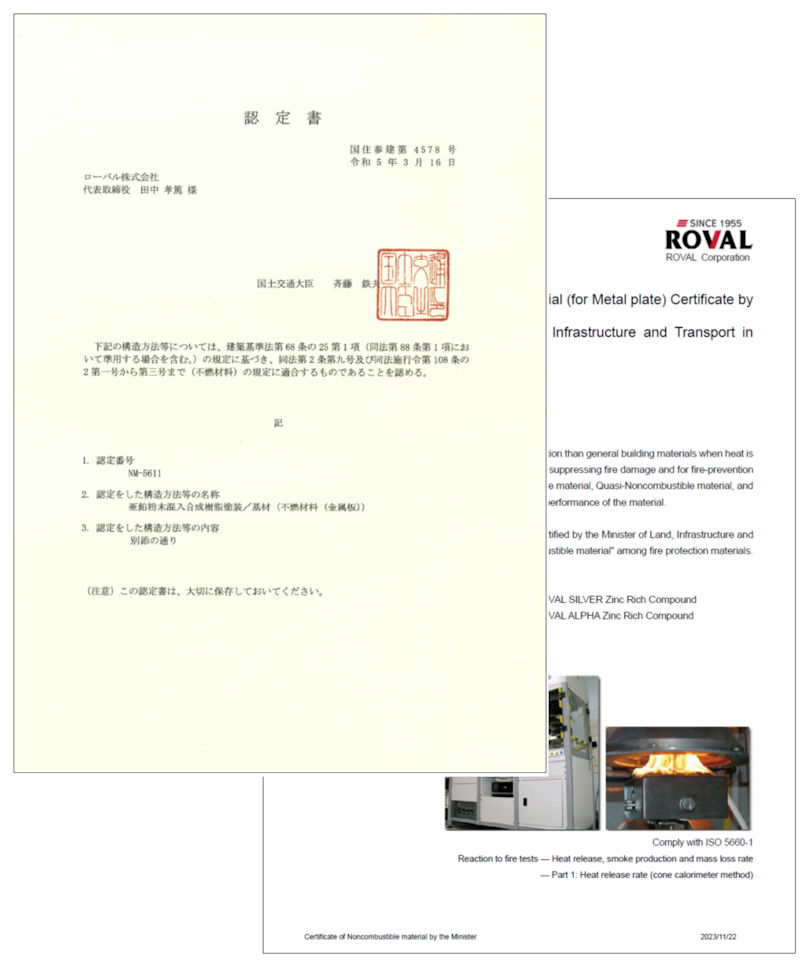

Noncombustible material certificate by the Minister

Noncombustible material certificate by the Minister

Fire protection materials are characterized by slower ignition than general building materials when heat is applied by a normal fire, and are used for the purpose of suppressing fire damage and for fire-prevention measures. It is classified into three types, Noncombustible material, Quasi-Noncombustible material, and Fire retardant material, depending on the fire protection performance of the material.

The ROVAL series painted on metal plates has been certified by the Minister of Land, Infrastructure and transport in Japan as the most incombustible “Noncombustible material” among fire protection materials.

ISO9001, ISO14001 Certificate

| ISO9001 in China (Shanghai ROVAL Zinc Rich Paint Corporation) |

| ISO14001 in China (Shanghai ROVAL Zinc Rich Paint Corporation) |

| ISO9001 in Japan (ROVAL Corporation) |

| ISO14001 in Japan (ROVAL Corporation) |

Other certificates

| Certificate of RoHS compliance |

| Specification and analysis report of ISO3549 |

| Specification and analysis report of ASTM D520 Type II |

TDS (Technical Data Sheet)